0091-11-25278301

An asphalt batch mix plant is an essential equipment in the road construction industry. Unlike continuous plants, this plant produces asphalt in batches, allowing for better control over quality and mix composition. It is widely used for highways, urban roads, airports, and infrastructure projects requiring high-quality asphalt production. As a leading asphalt batch mix plant manufacturer, Alfa Omega India provides high-performance solutions for modern road construction.

When comparing batch mixing plant vs drum mix plant, the key difference lies in the mixing process.

Batch Mixing Plant: Asphalt is produced in controlled batches, ensuring precise composition and quality. This method allows for flexibility in mix designs, making it ideal for projects requiring different asphalt grades.

Drum Mix Plant: This plant continuously produces asphalt without interruption, making it suitable for high-volume projects. However, it offers less flexibility in mix customization.

A batch mix plant is often preferred for projects demanding superior quality and flexibility.

To ensure efficient and high-quality asphalt production, an asphalt batch mix plant consists of the following essential components:

Cold Aggregate Feeder Bin

Drying Drum

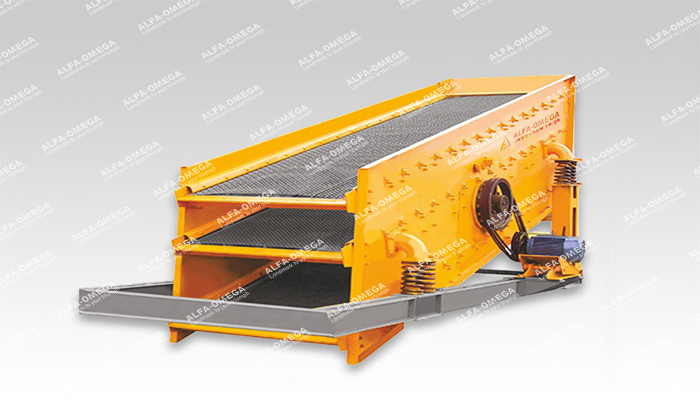

Vibrating Screen

Weighing and Mixing System

Bitumen Storage Tank

Pollution Control Baghouse Filter

Storage Silos

Hot Aggregate Elevator

Control Cabin

The asphalt batch mix plant process involves several crucial steps:

Cold Aggregate Feeding – Different-sized aggregates are fed into separate bins.

Drying and Heating – The aggregates are transferred to a drying drum, where moisture is removed.

Screening and Weighing – The hot aggregates pass through vibrating screens for proper grading and weighing.

Bitumen and Filler Addition – Heated bitumen and mineral fillers are added to the mix.

Batch Mixing – All components are blended in a mixer to produce a homogenous asphalt mix.

Storage and Loading – The final asphalt is stored in silos before being transported for road construction.

This well-structured process ensures consistent, high-quality asphalt production, making our asphalt batch mix plant a reliable choice for contractors.

As a trusted road construction equipment manufacturer, supplier, and exporter, we ensure:

High-Performance Machinery – Designed for maximum efficiency and durability.

Eco-Friendly Operations – Equipped with a pollution control baghouse filter for a cleaner environment.

Customization Options – Tailored solutions to meet diverse project needs.

Reliable After-Sales Support – Dedicated service and technical assistance.

Invest in a high-performance asphalt batch mix plant from Alfa Omega India and experience unmatched reliability, efficiency, and quality in every batch. Contact us today for the best solutions in road construction!

Copyright © 2026 Alfa Omega Enterprises. All rights reserved.

WhatsApp Chat

Request A Quote

WhatsApp Chat

Request A Quote