0091-11-25278301

In the fast-paced world of construction, time and efficiency are critical. As infrastructure demands grow, contractors and builders are looking for smarter and more flexible solutions for on-site concrete production. One innovation that has gained significant popularity is the mobile concrete batching plant. This equipment brings all the benefits of a stationary plant but with the added advantage of mobility. Whether you're working in urban locations or remote project sites, a mobile concrete plant is an efficient and cost-effective choice.

A mobile concrete batching plant is a portable version of a traditional concrete batching unit. It is designed to be transported from one site to another with ease. Unlike stationary plants, which are fixed to a specific location, movable concrete batching plants are mounted on wheels or trailers, making them highly adaptable to changing work environments.

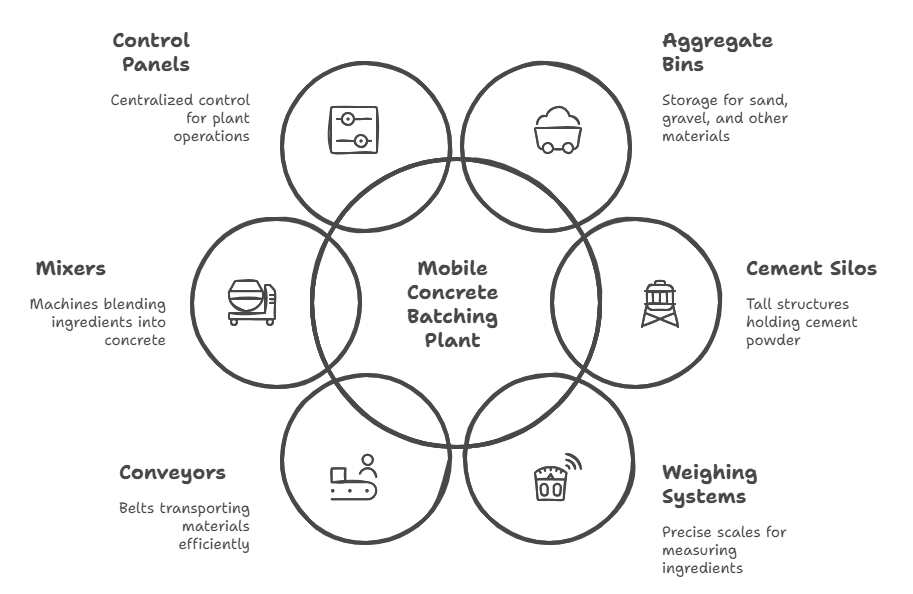

These plants typically include all essential components like:

The entire system is integrated in a compact design that can be assembled and disassembled quickly without requiring heavy foundation work.

The primary advantage of a mobile concrete batching plant is its portability. It allows builders to produce concrete on-site, reducing the need for multiple concrete delivery trips, which in turn cuts costs and project delays.

Since it doesn’t require a permanent foundation, setting up a mobile concrete plant is much faster. This makes it ideal for short-term construction projects or projects in remote areas.

When concrete is transported from a distant stationary plant, there's always a risk of delays, quality degradation, and increased transport expenses. A mobile unit minimizes these issues by producing concrete right where it's needed.

Modern mobile concrete batching plants come with automated control systems that ensure precise mixing of materials. This consistency leads to higher-quality concrete output.

Because of reduced transportation and precise batching, mobile concrete plants help minimize fuel consumption and material wastage, supporting sustainable construction practices.

India, being one of the largest construction markets in the world, has witnessed a rising demand for mobile batching solutions. From highway projects to smart cities and rural infrastructure, the need for portable, high-performance concrete solutions is booming.

Several projects in India are located in regions with limited access to ready-mix concrete suppliers. In such cases, a mobile concrete batching plant in India provides unmatched convenience and control over the construction process.

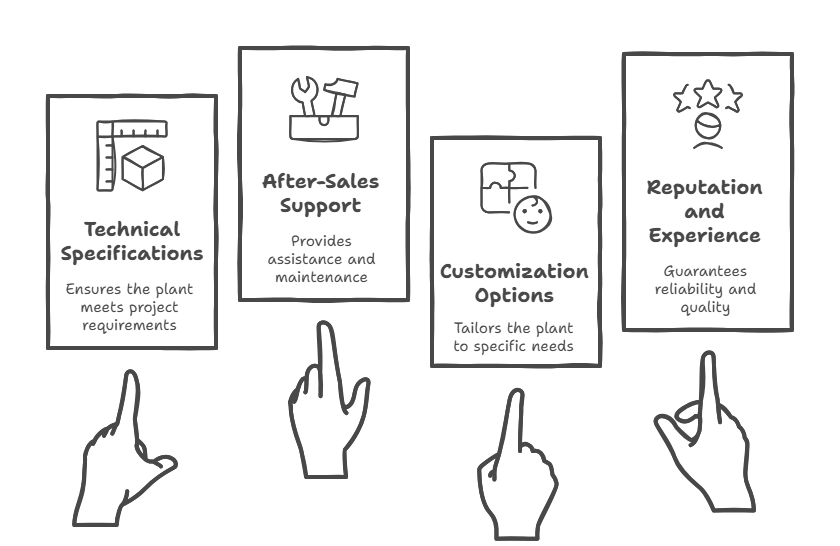

If you're planning to invest in a mobile batching unit, choosing the right mobile concrete batching plant manufacturer in India is essential. Here are some tips:

Road Construction Projects Mobile plants are perfect for highway construction where the location keeps changing frequently.

Remote Construction Sites In hilly or rural areas, transporting concrete from a distant plant is impractical. A movable concrete batching plant solves this problem efficiently.

Small to Medium Infrastructure Projects Projects with short deadlines or limited budgets can benefit from an on-site batching solution.

Emergency Projects Natural disasters or urgent repair work requires quick setup — something only mobile batching units can offer.

With the construction industry moving toward automation, digitization, and sustainability, the mobile concrete batching plant market in India and globally is poised for steady growth. Manufacturers are focusing on smart controls, IoT integration, and fuel-efficient designs to meet the evolving needs of the market.

Furthermore, the government’s focus on infrastructure development under initiatives like PM Gati Shakti, Smart Cities, and Bharatmala will only fuel the demand for mobile concrete batching plants in India.

A mobile concrete batching plant is more than just a piece of equipment — it's a productivity tool that helps contractors deliver quality, efficiency, and flexibility on every job site. Whether you're a small contractor or a large construction firm, investing in a mobile batching plant can significantly streamline your operations, especially in today's dynamic project environments.

With several reputed mobile concrete batching plant manufacturers in India, it's easier than ever to find a solution tailored to your specific needs. As construction continues to evolve, the mobile batching plant stands out as a smart, future-ready investment.

A stationary plant is fixed at one location and suitable for long-term projects, while a mobile concrete batching plant is portable and ideal for short-term or multi-location projects.

Capacities usually range from 15 m³/hr to 60 m³/hr, depending on the model and manufacturer.

Yes, most mobile concrete batching plant manufacturers in India offer customization based on material needs, space, and output requirements.

Installation typically takes 1 to 3 days, depending on the model and site conditions.

Yes, modern movable concrete batching plants can be scaled to meet large construction demands with high efficiency and consistent quality.

Copyright © 2026 Alfa Omega Enterprises. All rights reserved.

WhatsApp Chat

Request A Quote

WhatsApp Chat

Request A Quote

Leave a Reply

Your email address will not be published / Required fields are marked *