0091-11-25278301

In the rapidly advancing construction industry, the need for efficiency, accuracy, and mobility has never been greater. Infrastructure projects today demand equipment that can adapt to changing environments while ensuring consistent production quality. Among such technologies, the mobile concrete batching plant stands out as a game-changing solution. This equipment delivers high-quality concrete right at the project site, allowing contractors to achieve better control, faster progress, and reduced operational costs.

This comprehensive guide explains everything you need to know about the mobile concrete batching plant—its working mechanism, benefits, applications, and key features

A mobile concrete batching plant is a fully integrated, portable unit designed to produce concrete efficiently at construction sites. Unlike large stationary plants, a mobile plant is built on a single chassis with all essential components—including aggregate feeders, cement weighing systems, a mixer, a control cabin, and water tanks—assembled in a compact, transport-friendly structure.

It allows contractors to produce concrete directly where it is needed, eliminating delays caused by long-distance transportation or dependence on remote ready-mix suppliers. The compact design and mobility advantages make it ideal for projects that require quick movement between locations or operate in remote and difficult terrains.

A mobile concrete batching plant functions as a complete on-site concrete production system. Aggregates are loaded into hoppers, which feed materials into the weighing system. Using load-cell-based precision weighing, the plant accurately measures aggregates, cement, water, and additives according to the required mix design.

Once materials are weighed, they move into the mixer—typically a reversible drum mixer or twin-shaft system—where they blend uniformly to produce high-quality concrete. The entire process is governed by an advanced control panel that automates batching cycles, maintains mixing consistency, and records production data.

After mixing, concrete is discharged directly into transit mixers, pumps, or pouring areas based on the project’s requirements. The workflow is fast, efficient, and highly reliable, making the mobile concrete plant a dependable choice for modern construction companies.

One of the standout advantages of a portable concrete batching plant is its quick installation. Thanks to its modular, compact design, the plant requires minimal site preparation and can begin production within a few hours of arrival. This rapid setup significantly reduces project downtime.

The axle-mounted mobile structure allows contractors to shift the plant from one location to another efficiently. This flexibility is essential for linear and multi-phase projects such as highways, canals, and road widening works.

Its compact footprint makes it ideal for congested or urban job sites. Even in remote areas with limited space, the plant fits comfortably without demanding heavy foundations or elaborate infrastructure.

The load-cell-based weighing system ensures accurate measurement of all components, resulting in consistent, high-quality concrete across batches. This precision helps achieve stronger structures and better performance in real-world applications.

With durable mixers and efficient blending mechanisms, mobile concrete batching plants deliver uniform, reliable mixing. This ensures optimal workability, slump accuracy, and strength development—critical qualities for infrastructure-grade construction.

Designed with state-of-the-art components and efficient motors, these plants consume less power while maintaining high productivity. Optimized batching cycles further contribute to energy savings and lower operating costs.

Producing concrete on-site eliminates the need for long-distance transit, reducing transportation expenses and preventing material wastage caused by delays or traffic-related time losses.

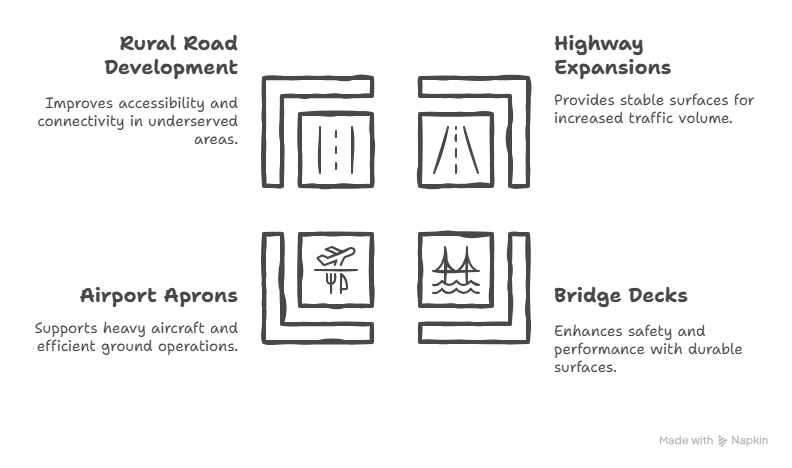

Road construction requires continuous concrete supply, predictable output, and flexibility. A mobile concrete batching plant is perfectly suited for such requirements. Its mobility allows the plant to move along the project as work progresses, ensuring steady production without interruptions.

The ability to customise mix designs, maintain uniformity, and respond quickly to field conditions makes mobile plants essential for:

Contractors appreciate the straightforward maintenance, stable performance, and adaptability that mobile concrete plants provide during high-volume roadwork.

Contractors choose portable concrete plants for their unmatched flexibility and cost-effectiveness. By producing concrete directly at the work site, these plants eliminate dependence on third-party suppliers, reduce production delays, and improve overall project efficiency. Their mobility allows contractors to move seamlessly between job sites, ensuring maximum equipment utilization and profitability.

Portable plants also offer better quality control, as contractors can monitor and adjust mix parameters instantly. This leads to improved structural performance and long-term durability of the constructed assets.

When selecting a mobile concrete plant, contractors should consider the following essential features:

Compact and modular structure for easy transport

High mobility with axle-mounted frames

Fast installation without complex civil foundations

Load-cell-based weighing for top-tier batching accuracy

Efficient mixing technology for superior concrete quality

Advanced automated controls (PLC/SCADA)

Energy-efficient motors and systems

Durable steel construction for long life

Low-maintenance design with easy access points

Manufacturers like Alfa Omega India are well-recognised for delivering robust and reliable mobile concrete batching plants specifically engineered for demanding construction environments.

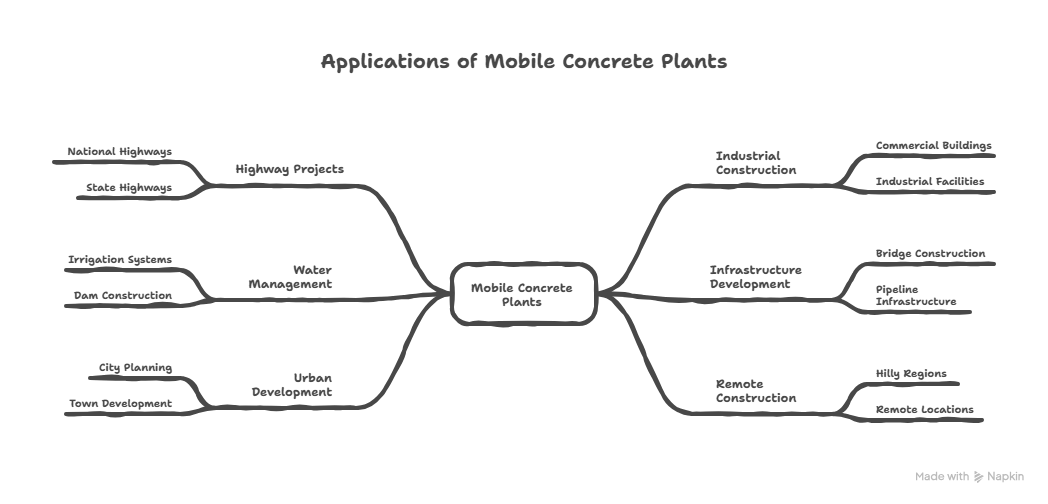

Mobile concrete batching plants are widely used across:

The plant’s ability to operate independently without heavy civil foundations makes it highly suitable for remote or difficult-to-reach work locations.

A mobile plant is mounted on a compact, transportable chassis and can be relocated quickly, while a stationary plant requires permanent installation with civil foundations. Mobile plants are ideal for multi-site and short-term projects, whereas stationary plants suit long-term, high-capacity installations.

A capacity of 30–60 m³/hr is commonly preferred for highway and road construction projects. It offers the ideal balance of mobility, output, and operational efficiency needed for linear construction work.

Contractors prefer portable plants because they reduce transportation costs, ensure continuous concrete supply, minimise wastage, and allow production flexibility at any stage of the project.

A mobile concrete batching plant is an essential asset for modern construction companies seeking efficiency, mobility, and high-quality concrete production. With advantages like compact design, fast installation, precision weighing, high-quality mixing, and energy efficiency, it significantly enhances on-site productivity. Trusted manufacturers like Alfa Omega India continue to deliver reliable, engineering-grade mobile plants that meet today’s demanding construction standards.

Equip your next project with a high-performance mobile concrete batching plant and experience smarter, faster, and more efficient construction operations.

Copyright © 2026 Alfa Omega Enterprises. All rights reserved.

WhatsApp Chat

Request A Quote

WhatsApp Chat

Request A Quote

Leave a Reply

Your email address will not be published / Required fields are marked *