0091-11-25278301

Ever driven on a freshly paved road and thought, "Wow, this feels so smooth"? You can thank a hot mix plant for that. If you’re wondering what exactly a hot mix plant is and why it matters in construction, especially for roads, let me walk you through it. Whether you're a civil engineer, contractor, or just someone curious about infrastructure, this is a must-know.

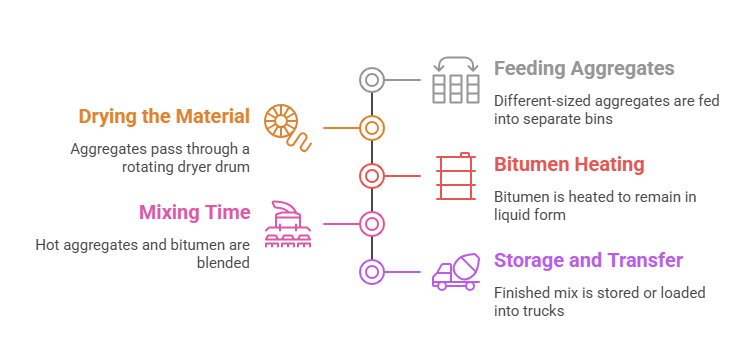

A hot mix plant is a setup used to prepare a blend of bitumen and aggregates (like sand, stone dust, or gravel) at high temperatures. This mix is laid on roads to create a durable, flexible surface that can handle traffic, weather, and time. The process involves heating, mixing, and transporting the final mix while it’s still hot. If the mix cools too soon, it won’t bond properly—timing is key.

Let’s be honest—roads are among the most used public assets, yet we barely notice their quality until we hit a pothole. A good road isn't just about looks; it’s about lasting performance. That’s where a hot mix plant steps in. It ensures the asphalt mix has the right texture and durability. Without it, highways and urban streets wouldn't survive a single monsoon. It also speeds up construction, critical when deadlines loom.

Cold Aggregate Feeder Bins – Store and regulate various aggregate sizes.

Dryer Drum – Heats and dries the aggregates.

Burner Unit – Provides the necessary heat.

Bitumen Tanks – Heat and store bitumen.

Mixing Unit – Where the actual mixing occurs.

Pollution Control Unit – Manages dust and emissions.

Control Panel – Operates the entire plant efficiently.

1. Batch Type Plant

Produces asphalt in controlled batches—ideal for precision but with a lower output rate.

2. Continuous Plant

As the name suggests, materials are continuously fed and mixed. The drum mix plant is a great example of this—compact, efficient, and widely used for time-sensitive projects.

Highways and Expressways

Urban Roads

Airport Runways

Industrial Roads

Your project’s success depends on reliable equipment. When choosing a supplier, prioritize experience, after-sales service, and customization. Alfa Omega India stands out here. As a reputable hot mix plant manufacturer, they offer durable, efficient machines backed by professional support and technical know-how.

The industry is going greener and smarter. Plants now feature advanced automation, digital quality monitoring, and energy-efficient systems. Also, the use of recycled materials like RAP (Reclaimed Asphalt Pavement) is gaining traction, promoting sustainability.

A hot mix plant may not get the spotlight, but it's the powerhouse behind modern roadways. If you're in road construction, investing in a reliable setup is non-negotiable. And with the right equipment partner, like Alfa Omega India—one of the trusted road construction equipment manufacturers in India—your project is in capable hands.

Copyright © 2026 Alfa Omega Enterprises. All rights reserved.

WhatsApp Chat

Request A Quote

WhatsApp Chat

Request A Quote

Leave a Reply

Your email address will not be published / Required fields are marked *