0091-11-25278301

In today’s industrial world, air quality has become a global concern. The continuous growth of manufacturing, construction, and energy production sectors has led to a significant rise in air pollution levels. This has created an urgent need for advanced and reliable pollution control equipment. Among the many technologies developed to combat this issue, the air pollution controller stands out as one of the most efficient and sustainable solutions for industries worldwide.

An air pollution controller is a mechanical or electrostatic system designed to remove contaminants, dust, and harmful gases from industrial exhaust streams before they are released into the atmosphere. These systems ensure that industrial operations comply with environmental regulations while protecting workers, communities, and ecosystems from hazardous air pollutants.

Air pollution controllers are used in a wide range of industries — including cement, steel, power plants, pharmaceuticals, and chemical manufacturing — where the production process generates particulate matter, smoke, and fumes. The technology behind these systems varies, but the goal remains the same: to minimize the release of pollutants and maintain clean air quality.

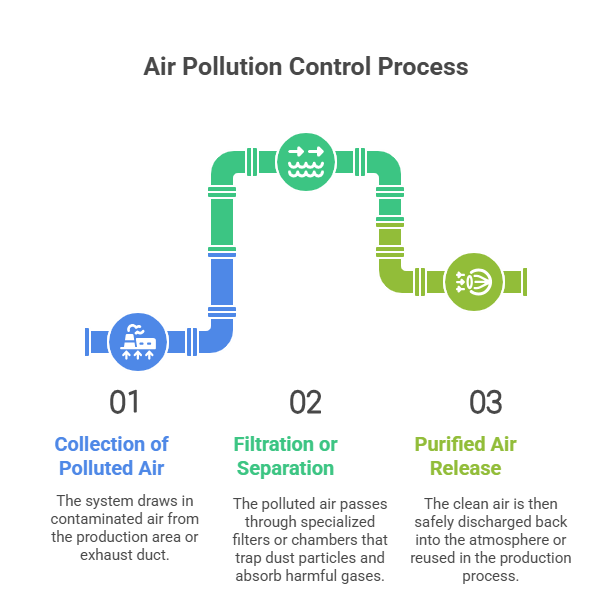

The working principle of air pollution controllers depends on the type of equipment used. However, most systems follow a similar process:

Different types of pollution control systems use varied mechanisms — such as filtration, cyclonic separation, or electrostatic attraction — to remove pollutants effectively.

One of the most commonly used air filtration systems is the baghouse filter. This device captures fine dust particles from industrial emissions using fabric filter bags. As dirty air passes through the filter media, dust particles adhere to the fabric surface, and only clean air is released.

Baghouse filters are highly efficient and can remove up to 99% of airborne dust, making them ideal for industries like cement, asphalt, metal fabrication, and foundries. Their modular design allows for easy maintenance, ensuring long-term performance with minimal downtime.

A dust collector is another essential component in modern pollution control equipment. It collects and stores dust and particulate matter from various industrial processes. Depending on the application, dust collectors can be cartridge-type, cyclone-type, or wet scrubbers.

These systems are widely used in woodworking, mining, and material handling industries. By keeping dust under control, they not only protect the environment but also improve indoor air quality and enhance worker safety.

An electrostatic precipitator uses electrical energy to remove dust and smoke from exhaust gases. It works by charging the particles electrically and then attracting them to oppositely charged collector plates. This method is especially effective in power plants and cement industries where high-volume gas cleaning is required.

Wet scrubbers use liquid — usually water — to capture and neutralize gaseous pollutants. They are particularly useful for removing acidic gases, fumes, and fine particulates. Their adaptability to handle different types of contaminants makes them a popular choice for chemical and pharmaceutical industries.

Industrial emissions contain pollutants that contribute to smog, acid rain, and global warming. By installing advanced pollution control equipment, companies can significantly reduce their carbon footprint and support a sustainable environment.

Exposure to fine dust and chemical fumes can lead to respiratory issues and other health complications. A properly designed air pollution controller ensures clean and safe working conditions for employees.

Government bodies across the world have established strict emission norms for industries. Using certified pollution controller equipment helps manufacturers stay compliant with environmental regulations and avoid heavy fines or shutdowns.

Dust and debris can damage machines and reduce their lifespan. Efficient air filtration systems prevent accumulation, leading to smoother operations and lower maintenance costs.

In industries like food processing and pharmaceuticals, maintaining clean air conditions is essential to product quality. Pollution control systems help ensure that production areas remain free from contaminants.

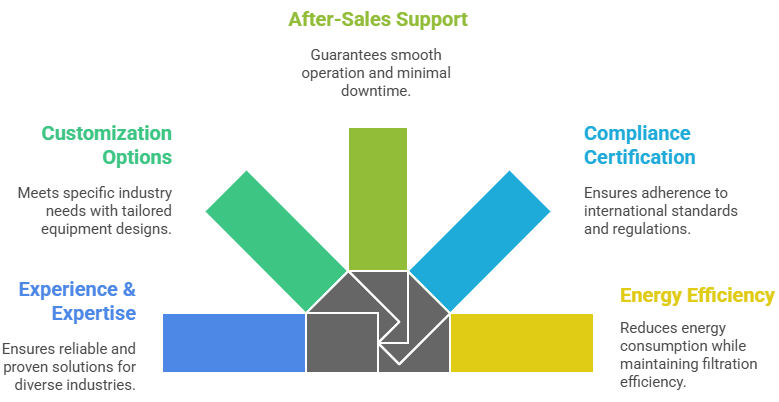

Selecting the right pollution controller manufacturer is crucial for achieving optimal performance and long-term reliability. When choosing a manufacturer, consider the following factors:

With increasing environmental awareness, technology in air pollution control has evolved rapidly. Here are some of the latest trends:

IoT-Based Monitoring: Smart sensors and IoT-based systems allow real-time monitoring of emissions, helping industries take immediate corrective actions.

Hybrid Filtration Systems: Combining mechanical filtration with electrostatic precipitation for superior air purification efficiency.

Energy Recovery Systems: Modern systems recycle captured heat from exhaust gases, improving overall energy efficiency.

Compact Modular Designs: Advanced compact systems are designed to fit smaller industrial spaces without compromising performance.

The demand for pollution control equipment is steadily growing, especially in emerging economies like India. With the Indian government emphasizing the “Make in India” initiative and enforcing strict pollution norms, industries are increasingly investing in modern air pollution control systems.

Leading pollution controller manufacturers in India are innovating to produce high-performance, eco-friendly, and cost-effective solutions that meet both domestic and global standards. This growth reflects a positive shift toward sustainable industrial development.

The world is moving toward a cleaner, greener, and more responsible industrial future. The use of advanced air pollution controllers is no longer optional—it’s a necessity. By integrating efficient systems like baghouse filters and dust collectors, industries can not only meet environmental regulations but also contribute to a healthier planet.

Choosing a trusted pollution controller manufacturer ensures reliability, performance, and long-term savings. As technology continues to advance, the future of air pollution control promises smarter, more efficient, and environmentally responsible solutions for every sector.

An air pollution controller is a system designed to remove harmful particles, gases, and dust from industrial exhaust before it’s released into the atmosphere. It works by drawing polluted air through specialized pollution control equipment like baghouse filters, dust collectors, or scrubbers. These devices capture particulate matter and clean the air, ensuring industries comply with environmental norms and maintain a safer working environment. Advanced controllers help reduce emissions and support sustainable industrial operations.

Pollution control equipment is crucial because it helps industries reduce harmful emissions that contribute to air pollution and health hazards. Devices like baghouse filters and dust collectors trap particulate matter, smoke, and chemical fumes, ensuring clean air within and outside the facility. Installing efficient air pollution controllers also ensures compliance with environmental regulations, prevents fines, and improves worker safety. Additionally, cleaner operations enhance equipment life, energy efficiency, and overall production quality.

There are several types of air pollution control systems designed for different industrial needs. Common types include baghouse filters, dust collectors, electrostatic precipitators, and wet scrubbers. Baghouse filters use fabric bags to trap dust particles, while electrostatic precipitators use electric charges to capture smoke and ash. Wet scrubbers remove gases and fine particles using liquid absorption. Each system offers unique benefits, but all aim to minimize air pollutants and promote sustainable industrial practices.

Choosing the right pollution controller manufacturer involves evaluating experience, technology, and support. A reliable manufacturer provides customized pollution control equipment tailored to your industry’s specific emission type and capacity. Look for companies with a proven track record, certified products, and excellent after-sales service. It’s also important to ensure they follow environmental standards and offer energy-efficient designs. In India, many leading manufacturers deliver high-quality, durable, and eco-friendly solutions that ensure long-term performance.

Industries that generate high levels of dust, smoke, or chemical fumes rely heavily on air pollution controllers. These include cement plants, steel manufacturing units, power plants, pharmaceuticals, food processing, and asphalt production. Using baghouse filters and dust collectors, these systems prevent pollutants from escaping into the air, ensuring environmental compliance and worker safety. With growing awareness about sustainable production, more industries are adopting advanced pollution control technologies to reduce emissions and improve air quality.

Copyright © 2026 Alfa Omega Enterprises. All rights reserved.

WhatsApp Chat

Request A Quote

WhatsApp Chat

Request A Quote

Leave a Reply

Your email address will not be published / Required fields are marked *