0091-11-25278301

In the ever-evolving world of road construction and infrastructure development, continuous plants play a vital role in ensuring the smooth and efficient production of asphalt. These plants are specifically designed for large-scale operations where high production output, consistent quality, and time efficiency are crucial.

Among the various types of asphalt plants, asphalt continuous plants—commonly referred to as drum mix plants or asphalt drum mix plants—have become the go-to solution for many contractors and infrastructure companies across the globe.

In this blog, we’ll take a deep dive into the world of continuous plants, how they function, their benefits, and why they’re essential in modern road construction.

A continuous plant is a type of asphalt plant where the entire process of heating, drying, and mixing of aggregates with bitumen is done in a single uninterrupted flow. Unlike batch plants, which produce asphalt in specific batches, continuous plants operate nonstop and are ideal for high-volume projects.

The key characteristic of a continuous asphalt plant is its ability to produce hot mix asphalt (HMA) continuously without any interruption in the process. This makes them highly suitable for projects where large quantities of asphalt are needed over an extended period.

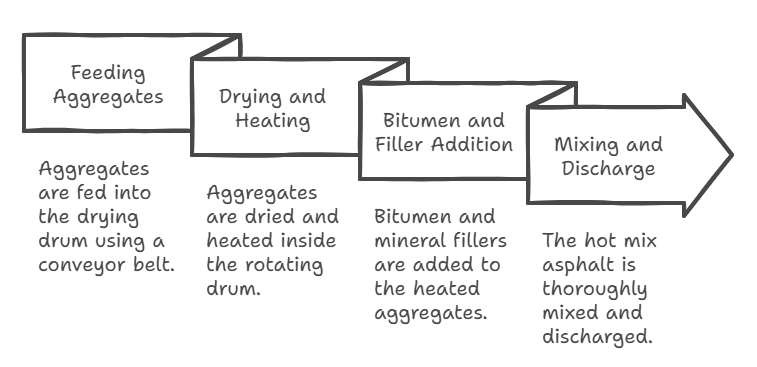

The working mechanism of a continuous drum mix plant is relatively straightforward, yet highly efficient:

The entire process is automated and controlled using a control panel, ensuring consistent quality and uniformity of the asphalt mix.

There are two major types of continuous plants:

These are versions of the portable asphalt continuous plant, ideal for projects in remote areas or where frequent relocation is required. They are compact, easy to transport, and quick to install.

Best suited for long-term or large-scale projects, continuous stationary plants are installed at a fixed location. They offer higher production capacities and are built for efficiency and durability.

Whether it’s a mobile or stationary version, drum mix plants offer several advantages:

As the name suggests, the plant produces asphalt continuously, which saves time and boosts productivity, especially important for tight project deadlines.

Since the process is streamlined and involves fewer components than batch plants, maintenance and operating costs are generally lower.

Modern burners and drying systems ensure minimal fuel consumption per ton of asphalt produced.

Fully automated control panels simplify plant operations, allowing operators to monitor and manage production with ease.

The continuous mixing process ensures a uniform mix, which is crucial for road durability and performance.

Asphalt drum mix plants are widely used in:

National and state highway construction

Airport runway surfacing

Urban road and expressway development

Rural road infrastructure

Industrial area paving

Their versatility and efficiency make them a preferred choice for both government and private sector projects.

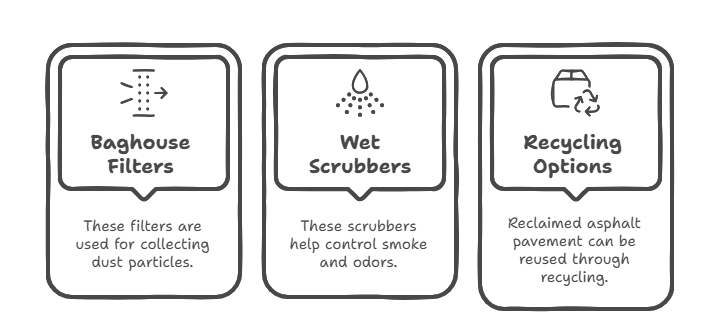

Modern asphalt continuous plants come equipped with advanced pollution control devices such as:

These features help reduce the plant’s environmental footprint and align with sustainable construction practices.

If your project demands high asphalt volumes with faster turnaround times, then investing in a drum mix plant is a strategic choice. Manufacturers today offer a range of asphalt drum mix plants that cater to different capacities and customization needs.

From ease of maintenance to robust performance, the asphalt continuous plant is a time-tested solution for modern road building challenges.

In the world of road construction, time, quality, and cost matter the most. Continuous plants, especially asphalt drum mix plants, are built to meet these demands effectively. Whether you're paving a new highway or resurfacing urban streets, these plants offer the reliability, scalability, and efficiency that infrastructure developers need.

A drum mix plant produces asphalt continuously, while a batch mix plant produces asphalt in batches. Drum plants are more suited for high-volume, time-sensitive projects.

Key components include cold aggregate feeders, a drying drum, a burner, bitumen tanks, a control panel, and pollution control units like bag filters.

Yes, mobile drum mix plants are designed specifically for remote and frequently shifting project sites. They are easy to transport and install.

Absolutely. Thanks to automated systems and continuous mixing, the asphalt quality remains consistent throughout the production cycle.

Modern drum mix plants come with pollution control devices and options for recycled asphalt usage, making them more eco-friendly than older models.

Copyright © 2026 Alfa Omega Enterprises. All rights reserved.

WhatsApp Chat

Request A Quote

WhatsApp Chat

Request A Quote

Leave a Reply

Your email address will not be published / Required fields are marked *